Screw Conveyors

Economical and Reliable Handling

Screw conveyors represent one of the oldest and most cost-effective methods for handling semi-solid bulk materials like drill cuttings.

Optional Features for Enhanced Control and Safety

Optional features include push-button electric start and speed control, safety gates, and an emergency stop device, allowing for enhanced control and safety during operation.

Screw Conveyor System for Sale

Contact your PSI representative to discuss your specific requirements and configure a system that perfectly suits your needs.

Customizable Conveyor

The PSI conveyor system consists of a range of stock components designed for easy assembly into custom configurations tailored to your specific material handling needs.

Rugged Drive Sections

Our drive sections feature robust motors and gearing specifically chosen to handle the weight and density of your materials effectively.

Durable Construction

All troughs are constructed from heavy-duty steel plate coated with industrial-strength epoxy paint, ensuring longevity and durability. Sealed hanger and end bearings support the steel auger, minimizing wear over time.

Super-Duty Coupling Shafts

Super-duty coupling shafts connect the auger between sections, providing seamless operation and preventing material spillage.

ENHANCED SAFETY OPTIONS

- Top mounted safety grates

- Remote stop switch

- Strobe light and alarm horn

- Side mount emergency pull cable

FEATURES

- Drive Section: The conveyor section has the gearbox and motor mounted either directly to it, or in closest proximity. This section consists of the drive and all of its components, such as the trough endplate, screw, trough and cover. For a pulling conveyor, a discharge spout is fixed to the trough, typically close to the drive, to maximize the conveying length.

- Midsection: The conveyor section couples to the drive section when three or more sections are joined together. The midsection consists of a trough, screw, cover, hanger frame, hanger bearing and coupling shaft. The midsection contains the least number of parts.

- Tail Section: The tail section is the “terminal end” of the system. It has a discharge spout when set up as a pushing system. This section is farthest away from the drive section and follows the midsections. The tail section consists of all the same components as the midsection—plus a trough end flange, waste pack seal, tail shaft and the idle end bearing. The idle end bearing can be mounted either directly to the trough endplate, or a pillow block bearing can be used.

Product Categories

Industrial Pumps

Industrial pumps move liquids and slurries for various applications in water treatment, wastewater management, food processing, manufacturing, factories, plants, and worksites.

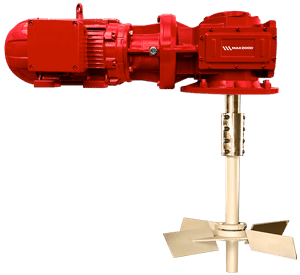

Material Handling Equipment

This category includes three essential products that cater to various material handling needs: the MAX2000 Mud Agitators, Screw Conveyors, and High Shear Hoppers.

Gas Management Systems

Gas management systems are vital for controlling the entrained gasses during these operations. Here’s a closer look at some of the top systems in this category.

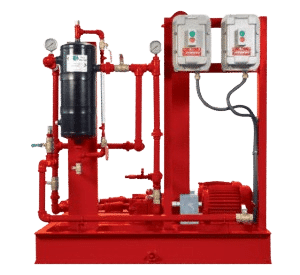

Fuel Filtration Systems

Our range of fuel filtration systems is designed to enhance and simplify your operations, saving you time and costs and ensuring a cleaner and safer working environment.