Gas Management Systems

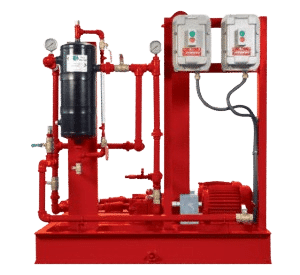

VAK 500®/1000®/1200® Vacuum Degassers

Features

- Robustness: Driven by a 5 hp TEXP motor, designed for continuous running.

- High Performance: Delivers up to 29″ Hg vacuum, making it perfect for thick fluids.

- User-friendly: Comes with an easy push-button start for convenient control.

- Compact and Durable: Skid-mounted, with a corrosion-resistant internal surface.

-

Reliability: Fewer moving parts mean more dependable operations.

Motor Power

TEXP 5 hp motor with a starter and fan guard.

Performance

Can achieve up to 29″ Hg, ideal for viscous fluids.

Safety

Includes a fail-safe overflow valve and a low-maintenance float assembly.

Convenience

Easy access points for maintenance and a compact design for straightforward placement.

Atmospheric Degassers

Features

- Efficient Operation: Processes fluid to within 16 PPG at a rate of up to 600 GPM.

- Versatility: Two models are available for different pit depths.

- Safety and Durability: Explosion-proof starter/motor combination with high-quality construction.

Quality

Made with 95 Shore A durometer polyurethane, offering heat and abrasion resistance.

Flow Rate

Ensures 500 GPM, effectively removing sand-size solids ranging from 40-100 microns.

Maintenance

Fast and straightforward cleaning, with replaceable parts.

Readiness

Shipped fully assembled and ready for installation.

Mud Gas Separators

Areas We Serve

At Process Solutions International, our expertise in fluid handling equipment spans across major global markets. Proudly serving Houston and New York, we extend our specialized services to the strategic regions of Saudi Arabia and all GCC countries. Our commitment to excellence ensures reliable, high-quality solutions wherever our clients need us. Connect with us to learn how our products can support your operations in these key areas.

Contact Us

Whether you’re looking for vacuum, atmospheric degassers, or even mud gas separators, opting for systems that promise reliability, safety, and efficiency is essential. The right gas management system can significantly enhance your drilling operations, ensuring smooth and safe drilling activities.

Product Categories

Industrial Pumps

Industrial pumps move liquids and slurries for various applications in water treatment, wastewater management, food processing, manufacturing, factories, plants, and worksites.

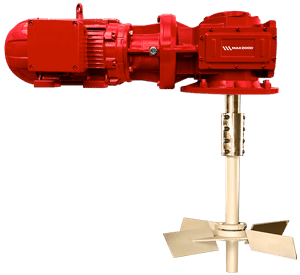

Material Handling Equipment

This category includes three essential products that cater to various material handling needs: the MAX2000 Mud Agitators, Screw Conveyors, and High Shear Hoppers.

Gas Management Systems

Gas management systems are vital for controlling the entrained gasses during these operations. Here’s a closer look at some of the top systems in this category.

Fuel Filtration Systems

Our range of fuel filtration systems is designed to enhance and simplify your operations, saving you time and costs and ensuring a cleaner and safer working environment.