Material Handling Equipment

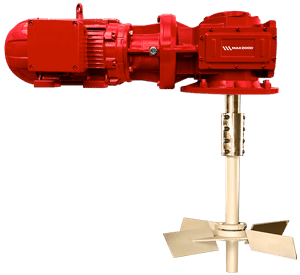

MAX2000® MUD AGITATORS

High Efficiency

The gear sets are made to minimize backlash, which boosts the unit’s life. The helical bevel gear stage boasts a 98% efficiency.

Adaptable Lubrication

Internal gears and bearings use mineral oil. However, for extreme temperatures, a synthetic lubricant is recommended.

Easy Maintenance

A standout feature is the lower bearing that can be maintained from the tank’s top, removing the need for in-tank inspections.

Protection

Four layers of protection keep the lower bearing constantly in touch with uncontaminated lubricant.

MAX2000® MUD GUNS

Effective Particle Management

Our MAX2000® Mud Guns prevent solid buildup in tank corners and aid in the mixing and suspension of particles.

Durability

Made of durable materials, they ensure longevity and efficiency.

Efficiency

Mud Guns effectively reduces solid buildup in tank corners.

Versatility

Mud Guns create alternative product flows with agitators.

User-Friendly

Mud Guns are available with handles for ease of rotation.

SCREW CONVEYORS

Enhanced Safety Options

- A remote switch to halt operations quickly

- Attention-grabbing strobe light and alarm horn

- A side-mounted emergency pull cable

Top Section

Grates on top for added safety

Drive Section

Houses the gearbox, motor, and other essential components

Midsection

This couples to the drive section and has the least parts, making it streamlined.

Tail Section

Contains components similar to the midsection with trough end flange and waste pack seal

HIGH SHEAR HOPPERS

- High-speed 6″ Mixing Eductor with a durable Urethane Nozzle & Diffuser

- Pre-wetter line for powders

Durability

A spacious 24″ conical hopper made of 304 Stainless Steel

Efficiency

4″ suction vacuum gauge for monitoring

Functionality

Quick disconnect through Groove-type connections

Operation

Operates at pressures between 40-50 psi

Product Categories

Industrial Pumps

Industrial pumps move liquids and slurries for various applications in water treatment, wastewater management, food processing, manufacturing, factories, plants, and worksites.

Material Handling Equipment

This category includes three essential products that cater to various material handling needs: the MAX2000 Mud Agitators, Screw Conveyors, and High Shear Hoppers.

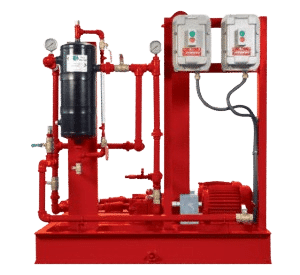

Gas Management Systems

Gas management systems are vital for controlling the entrained gasses during these operations. Here’s a closer look at some of the top systems in this category.

Fuel Filtration Systems

Our range of fuel filtration systems is designed to enhance and simplify your operations, saving you time and costs and ensuring a cleaner and safer working environment.