Progressing Cavity, Centrifugal, and Self-Priming Industrial Pumps

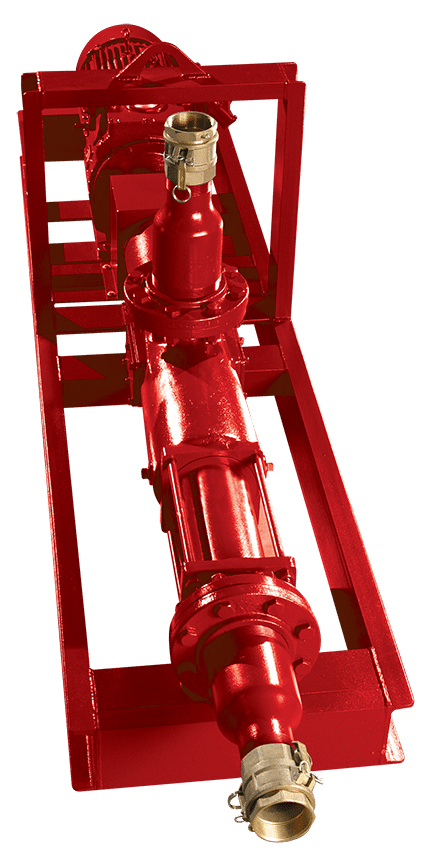

Progressing Cavity Pumps

Application

Progressing cavity pumps are commonly used to pump:

- Sludges

- Slurries

- Viscous liquids

- Food products

- Mud and concrete

Features

- Steady Flow: The liquid moves in a smooth, constant stream.

- Handles Thick Liquids: Great for a low sheer application like dewatering and barite recovery.

- Uses: Often seen in oil, food, and wastewater industries.

Benefits

- Gentle Movement: It doesn’t harm sensitive liquids.

- Less Clogging: Solids and particles in the liquid won’t easily stop this pump.

Efficient Fluid Extraction

Self-priming pumps efficiently draw fluid from sources such as wells or sumps without requiring a separate priming tank.

Versatile Applications

Ideal for installations where the pump is situated below the fluid level, these pumps come in various configurations to handle a wide range of fluids.

Intuitive Mechanism

Their operation is comparable to drinking a thick shake with a straw; they eliminate air first and then move the liquid, ensuring smooth performance.

Integrated Features

With the integrated air separator & check valve system, centrifugal pumps automatically reprime & evacuate air from the suction line before operation.

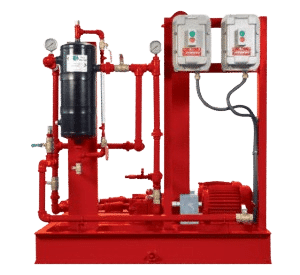

Centrifugal Pumps

Application

Centrifugal pumps have many industrial applications, including:

- Transferring water, oils, and chemicals

- Circulating water in heating and cooling systems

- Moving liquids through pipelines

- Feeding water to boilers and condensers

- Transferring corrosive fluids

Features

- Simple Design: These pumps have few parts, making them easy to maintain.

- High Flow Rates: They can move a lot of liquid quickly.

- Uses: Common in industries like water treatment and chemical processing.

Benefits

- Efficient: They use energy well, which can save money.

- Versatile: Can handle various liquids, from water to some chemicals.

Explore the centrifugal parts list here.

Uses

Industrial pumps are crucial for moving liquids and slurries, as water treatment, wastewater management, food processing, manufacturing, factories, plants, and worksites.

Types

Centrifugal pumps, progressing cavity pumps, and self-priming pumps are the main types of industrial pumps, each functioning differently to transfer fluids effectively.

Versatile

Centrifugal pumps utilize rotational energy to transfer fluids and are suitable for various applications due to their versatility and efficiency.

Self-Priming

Progressing cavity pumps and self-priming pumps offer unique advantages and are ideal for specific applications, providing tailored solutions depending on the fluid transfer requirements.

Self-Priming Pumps

Application

- Draining water or liquids from tanks and sumps

- Transferring liquids over long distances

- Applications where the pump may need to reprime frequently

- Situations where the pump may run dry temporarily

They provide versatility for pumping fluids from depths.

Features

- Starts Easily: It doesn’t need to be filled with liquid before starting.

- Handles Mixed Fluids: Good for liquids with some gas or air.

- Uses: Popular in industries with liquids that have bubbles, like some chemical processes.

Benefits

- Less Work: You can skip filling it up to start.

- Reliable: It can start and stop often without problems.

Functionality

Self-priming pumps are engineered to draw fluid from sources like wells or sumps without requiring a separate priming tank, simplifying installation and operation.

Suitability

These pumps are particularly ideal for scenarios where the pump is situated below the fluid level, offering versatility in deployment across different applications.

Mechanism

Their operational mechanism is comparable to drinking a thick shake with a straw, wherein they first eliminate air before efficiently moving the liquid, ensuring smooth & uninterrupted operation.

Efficiency

Equipped with an integrated air separator and check valve system, self-priming centrifugal pumps can automatically reprime and evacuate air from the suction line before operation.

Areas We Serve

At Process Solutions International, our expertise in fluid handling equipment spans across major global markets. Proudly serving Houston and New York, we extend our specialized services to the strategic regions of Saudi Arabia and all GCC countries. Our commitment to excellence ensures reliable, high-quality solutions wherever our clients need us. Connect with us to learn how our products can support your operations in these key areas.

Contact Us

Please contact Process Solutions International if you need help choosing the right industrial pump for your application. Our team of experts can help you find the perfect pump for your needs.

Product Categories

Industrial Pumps

Industrial pumps move liquids and slurries for various applications in water treatment, wastewater management, food processing, manufacturing, factories, plants, and worksites.

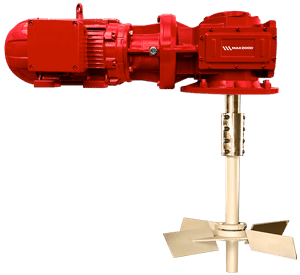

Material Handling Equipment

This category includes three essential products that cater to various material handling needs: the MAX2000 Mud Agitators, Screw Conveyors, and High Shear Hoppers.

Gas Management Systems

Gas management systems are vital for controlling the entrained gasses during these operations. Here’s a closer look at some of the top systems in this category.

Fuel Filtration Systems

Our range of fuel filtration systems is designed to enhance and simplify your operations, saving you time and costs and ensuring a cleaner and safer working environment.