MAX2000® Progressive Cavity Pumps

Unmatched Reliability, Unrivaled Performance

The MAX2000® Progressing Cavity Pumps feature highly reliable pumping characteristics that allow the user to monitor fluid rates with precision in applications from environmental remediation to food service industries.

Applications

Ideal for a myriad of industrial uses, from environmental remediation to the food service industry, our MAX2000® Progressing Cavity Pumps stand as a testament to reliability and efficiency.

Progressive Cavity Pumps for Sale

Invest in the reliability and performance of MAX2000® Progressing Cavity Pumps for your oil & gas industrial needs.

Proprietary Double-Seal Pin Joint

Eliminates contamination risks

Modular Design

Easily adjustable pumping characteristics

Extended Unit Life

Minimized downtime with rugged, system-matched maintenance parts

Skid-Mounted

Effortless transport and setup

FEATURES

- The MAX2000® Progressing Cavity Pump features the only double-seal pin joint in the industry. With improved technology, the “donut” style joint seal has been enhanced. By providing a “boot”, the joint is sealed with amazing reliability. When installed correctly, the boot clamps compress the boot to seal each joint with more than one inch of linear sealed surfaces. This greatly minimizes the potential for contamination of the joint.

- As with centrifugal pumps, we have created a modular design in the MAX2000® Progressing Cavity Pump. This modular design minimizes the need for customers to stock a wide variety of components. In doing so, it is now very easy to change the pumping elements, and alter the pumping characteristic of the MAX2000® Progressing Cavity Pump.

- Unlike most progressive cavity pumps sold in the United States, approximately 98% of the components in our MAX2000® Progressing Cavity Pumps are manufactured in the United States by craftsmen who take great pride in their workmanship.

Product Categories

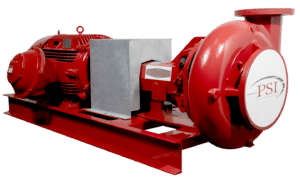

Industrial Pumps

Industrial pumps move liquids and slurries for various applications in water treatment, wastewater management, food processing, manufacturing, factories, plants, and worksites.

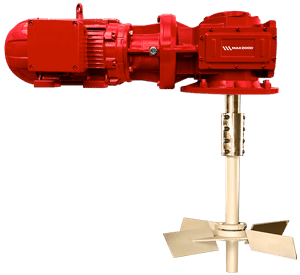

Material Handling Equipment

This category includes three essential products that cater to various material handling needs: the MAX2000 Mud Agitators, Screw Conveyors, and High Shear Hoppers.

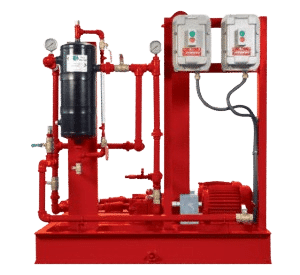

Gas Management Systems

Gas management systems are vital for controlling the entrained gasses during these operations. Here’s a closer look at some of the top systems in this category.

Fuel Filtration Systems

Our range of fuel filtration systems is designed to enhance and simplify your operations, saving you time and costs and ensuring a cleaner and safer working environment.