Exploring Different Industrial Pumps for Various Applications

Industrial pumps are the backbone of many industries, handling essential tasks like fluid transfer, material processing, and system maintenance. From water circulation to chemical handling, these pumps are critical for keeping operations running smoothly. However, different applications demand different types of pumps. At Process Solutions International (PSI), we provide a variety of industrial pumps designed to meet the unique needs of your industry.

Why Choosing the Right Industrial Pump Matters

Picking the right pump is not just a box to check—it’s essential for safety, efficiency, and performance. A pump that’s well-matched to your operation helps reduce downtime, lowers maintenance costs, and ensures reliable performance under various conditions. Whether it’s dealing with corrosive chemicals, managing high pressures, or handling abrasive slurries, choosing the right pump makes all the difference.

Common Types of Industrial Pumps

Here’s a closer look at some widely used industrial pumps and their ideal applications.

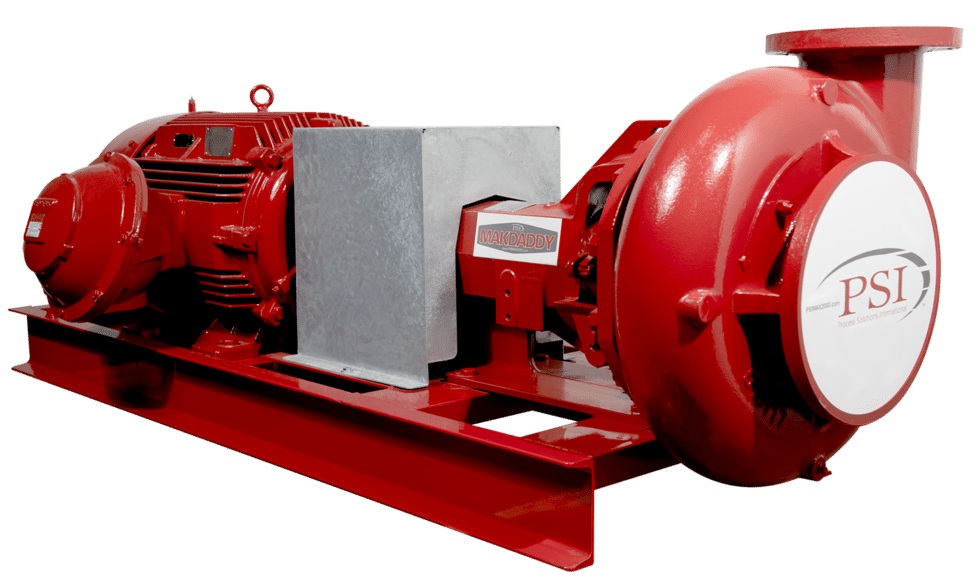

1. Centrifugal Pumps

Centrifugal pumps are among the most popular industrial pumps due to their simple design and versatility. They rely on a rotating impeller to generate fluid flow and are best suited for low-viscosity liquids like water or light oils.

Common Applications for Centrifugal Pumps:

- Water circulation

- Chemical and fluid transfer

- Wastewater management

Benefits of Centrifugal Pumps:

- Easy to maintain and operate

- Cost-effective for moving large volumes

- Reliable for continuous use

2. Self-Priming Pumps

Self-priming pumps are ideal for applications where the pump needs to reprime frequently or might run dry temporarily. These pumps are designed to handle liquids with some air or gas, making them versatile for various tasks.

Applications:

- Draining water or liquids from tanks and sumps

- Transferring liquids over long distances

- Situations requiring frequent reprime cycles

- Tasks where the pump might temporarily run dry

Features:

- Starts Easily: No need to fill it with liquid before starting.

- Handles Mixed Fluids: Performs well with liquids that contain air or gas bubbles.

- Uses Across Industries: Great for chemical processes involving bubbling liquids.

Benefits:

- Less Maintenance: No need to manually prime the pump.

- Reliable Performance: Tolerates frequent cycling without compromising functionality.

Self-priming pumps provide an efficient solution for transferring liquids, reducing operational hassle.

3. Progressing Cavity Pumps

Progressing cavity pumps excel when it comes to managing thick, viscous, or delicate materials. With their smooth and consistent flow, they’re a favorite in industries where product integrity is a top priority.

Ideal Uses for Progressing Cavity Pumps:

- Wastewater treatment

- Food-grade material handling

- Pumping sludges, slurries, and other viscous products

Benefits of Progressing Cavity Pumps:

- Precise, controlled flow

- Minimal product shearing, preserving sensitive materials

- Designed for challenging and abrasive media

How PSI Can Help

At PSI, we understand the complexities of industrial operations and the critical role pumps play in their success. That’s why we offer a wide range of industrial pumps, including centrifugal, self-priming, and progressing cavity pumps. Our team works closely with you to assess your specific requirements and recommend the best solution.

Not only do we supply industrial pumps, but we also provide maintenance support with OEM parts for industrial pumps to ensure your systems stay efficient and reliable. With PSI, you gain a partner focused on helping you streamline your operations and reduce downtime.

Industrial Solutions You Can Trust

The right industrial pump can improve efficiency, reduce downtime, and maximize productivity. At Process Solutions International, we’re committed to providing high-quality pump solutions tailored to your needs. Contact us today to learn more about our products and services or to request a detailed quote.