Brake Cooling Systems

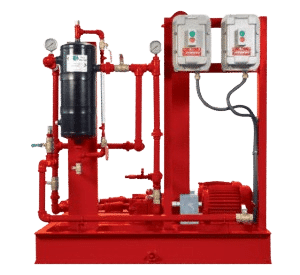

Process Solutions International (PSI) specializes in engineering brake cooling units customized to your specific parameters and requirements. Unlike standard products, each brake cooling unit is meticulously tailored by our manufacturing and design team to exact project criteria, leveraging their extensive knowledge and expertise.

With the exponential advances in control components, there is a wide array of options that can be seamlessly integrated into your unit for enhanced functionality.

Customized Performance for Every Project

- Robust Construction: Plate and same-style heat exchangers, along with premium 250 series pumps, are mounted and hard-piped on a robust I-Beam Framed skid, ensuring durability and structural integrity.

- Maximum Structural Integrity: Skids are covered with diamond plate and fully seal-welded to ensure maximum structural integrity, providing reliability even in demanding environments.

Customized Engineering

Each brake cooling unit is engineered to your specific parameters and requirements, ensuring optimal performance and reliability for your application.

Tailored Design

Our manufacturing and design team utilizes their expertise to tailor every unit to exact project criteria, guaranteeing a precise fit and functionality.

Advanced Control

With exponential advances in control components, a wide array of options can be seamlessly integrated into your unit, allowing for enhanced control and monitoring capabilities.

Quality Components

Major components include a heat exchanger providing full heat dissipation at 100% brake load, and a redundant centrifugal pump for circulating cooling fluid between the heat exchanger and reserve tanks.

FEATURES

PSI Brake cooling unit comes standard with the following features:

- Redundant centrifugal pumps

- Plate type heat exchanger

- Tank with sight glass and 6″ vent

- Analog temperature and pressure gages

- Assembled on a heavy duty skid with a four point lift and diamond floor plating.

- Skid is blasted, primed and painted

- Unit is function tested at PSI’s facility

- All electrical components are suitable for hazardous environments.

- Starters for the pumps with run indicator lights.

OPTIONS INCLUDE:

- Flow sensor for both the brake water and raw water

- Temperature sensor for the brake water.

- Level switch for the tank

- Green and red indicator lights for each starter and all sensors

- Horn to sound when a sensor is tripped, ie no flow, excessive temperature, or a pump amps out

Product Categories

Industrial Pumps

Industrial pumps move liquids and slurries for various applications in water treatment, wastewater management, food processing, manufacturing, factories, plants, and worksites.

Material Handling Equipment

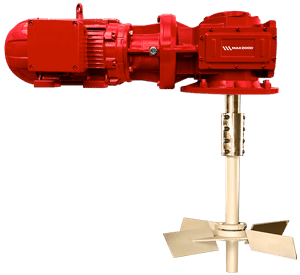

This category includes three essential products that cater to various material handling needs: the MAX2000 Mud Agitators, Screw Conveyors, and High Shear Hoppers.

Gas Management Systems

Gas management systems are vital for controlling the entrained gasses during these operations. Here’s a closer look at some of the top systems in this category.

Fuel Filtration Systems

Our range of fuel filtration systems is designed to enhance and simplify your operations, saving you time and costs and ensuring a cleaner and safer working environment.